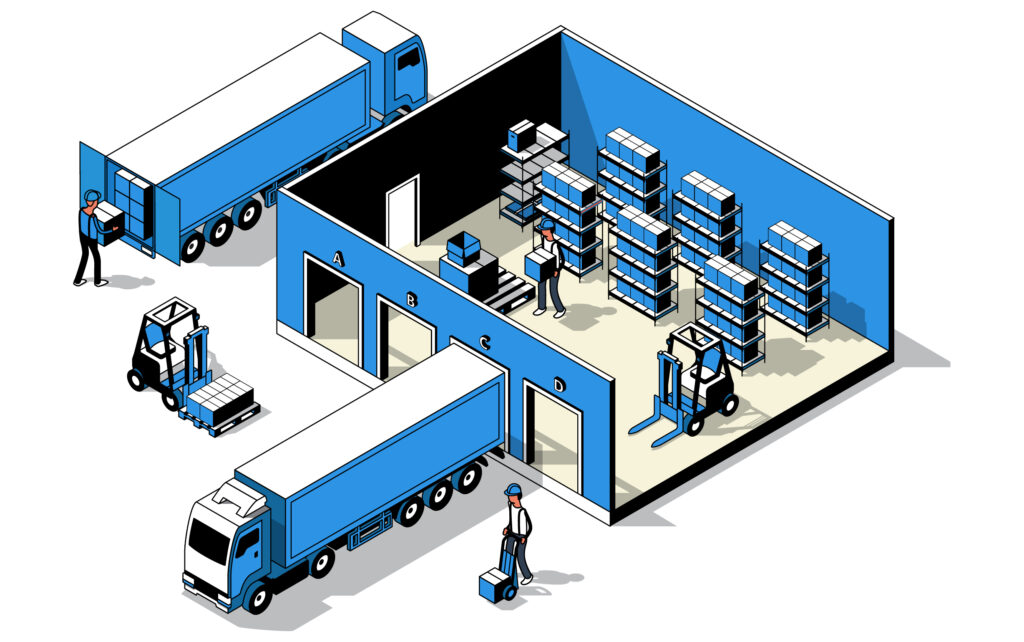

Modern trade operations are changing through intelligent systems that create smooth coordination between suppliers and distribution points. Businesses now depend on third party logistics to control inventory, tracking, and communication under one connected structure. Advanced tools handle product flow more efficiently and improve order precision. Automation inside warehouses strengthens data flow and delivery speed across global lines. Predictive insights ensure fewer delays and improve accuracy in each transaction. The use of modern systems has brought new structure, faster reporting, and stronger transparency across every operational layer.

Strengthening Distribution through Connected Innovation

Data-driven technology has become a central element of shipping progress. Integrated control systems now manage all phases of product movement without human error. Intelligent solutions monitor time-sensitive cargo and increase reliability. Collaboration tools synchronize data between suppliers and carriers, ensuring smooth performance.

Technology-Driven Freight Process Enhancement

New technologies simplify product movement through organized tracking. Digital mapping has reduced uncertainty in delivery schedules.

- Warehouse automation minimizes unnecessary waiting during dispatch stages

- Predictive tools evaluate product demands and support capacity management

- Data recording maintains consistent transparency among shipping partners

- Smart applications improve communication between handlers and storage staff

- Freight tracking reduces lost packages through constant visibility

- Advanced systems save cost through accurate route forecasting

- Order management tools enhance fulfillment quality across all zones

- Data sensors provide real-time progress for every shipment

Creating Reliable Global Operation Networks

Modern connectivity merges communication systems across every processing unit. This combination allows workers to react faster to any irregularity. Streamlined collaboration improves overall speed and customer reliability. Integrated software builds a continuous flow that strengthens long-term operational trust.

How Do Automated Systems Improve Global Handling Accuracy?

Efficient data-based systems transform warehouse and freight operations through active tracking tools. Predictive modules identify delivery challenges faster, ensuring better continuity. Automation now handles repetitive work that once slowed coordination.

Optimizing Real-Time Inventory Updates

Instant updates now assist workers in monitoring quantity and demand flow. Stock visibility helps avoid excess storage and loss of movement accuracy. Continuous monitoring supports steady performance in third-party logistics across varying conditions.

Intelligent Integration for Consistent Global Movement

Collaborative systems connect suppliers and buyers through organized data chains. These connections reduce dependency gaps and maintain efficiency under shifting conditions. Predictive reports assist businesses in reshaping their operating procedures for long-term stability.

Strong Foundation for Supply Progress

Every connected operation now relies on structured digital coordination. Intelligent systems create a path for error-free product handling. Data-driven insights ensure each transaction remains efficient and traceable. The new model of managed automation builds consistent value and stability across industries. Advanced coordination will continue shaping a secure and efficient future for global supply operations.